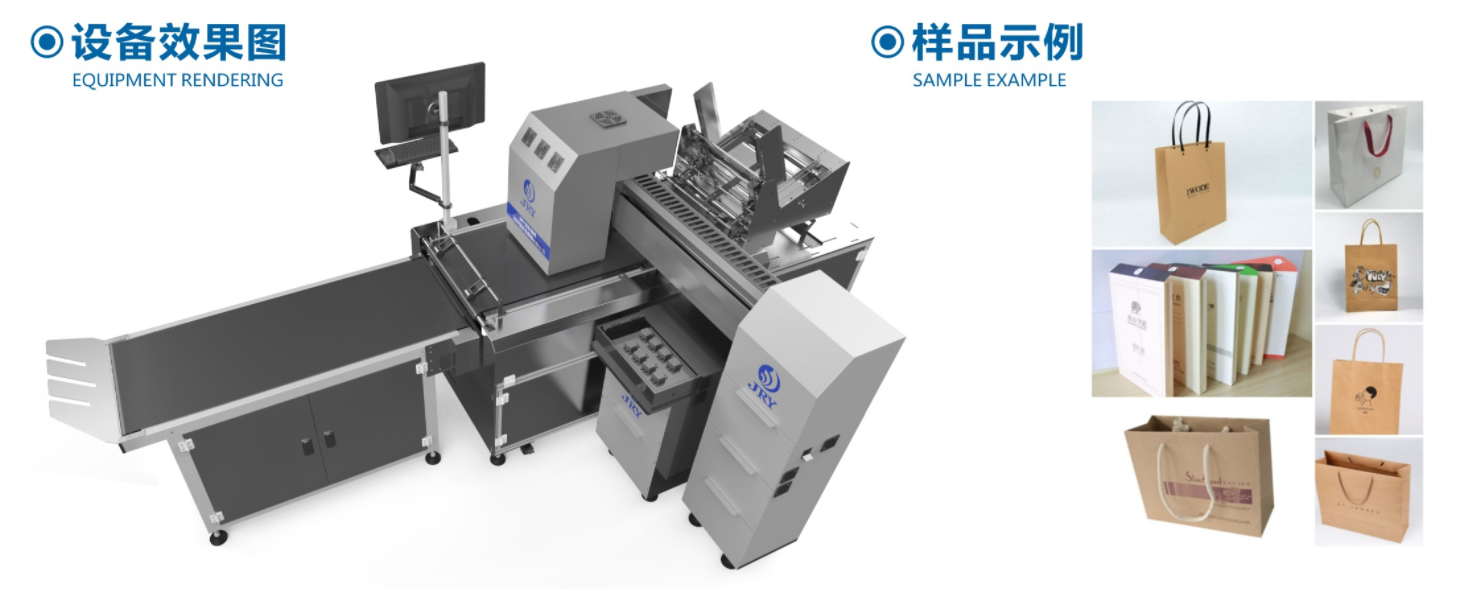

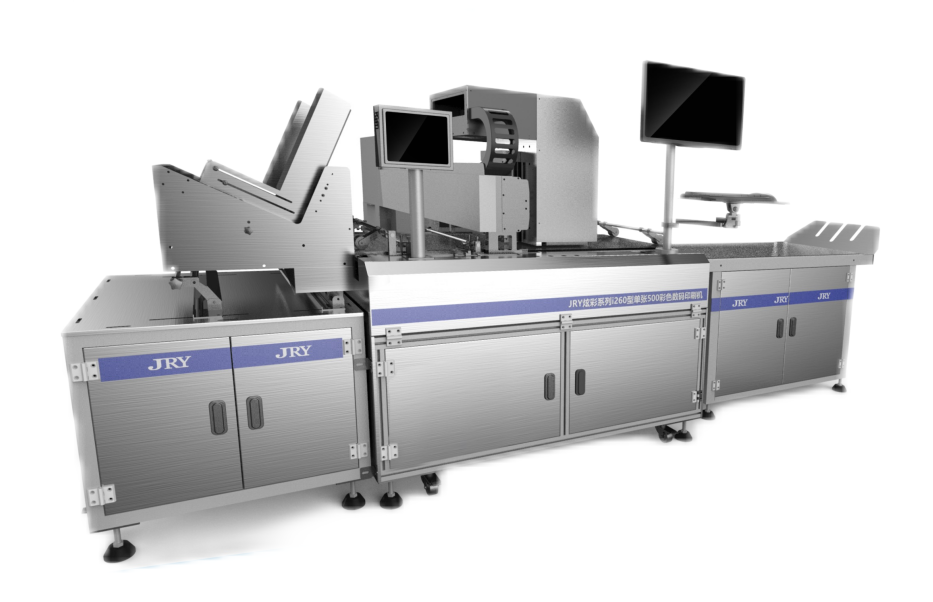

JRY Xuancai Series i260D-D/330D-D AQ Sheet-fed Color Digital Printing Machine is for small quantities of customized products, such as paper bags, cardboard, tea bags, cotton paper, archival bags, filter bags, filter cotton and etc. Material feeding way is single sheet of material, the maximum width is 500mm. There are two print widths: 260mm and 330mm. The equipment is configured with positioning device, and it owns high positioning accuracy. The resolution of each standard 4-colour ink channel is 600 dpi. Using environmentally friendly water-based pigment ink, the spray printing will dry at once with no additional infrared drying device required.The equipment is intellectualization, automation, and easy to operate.

consult< BACK

consult< BACK

Printing part of the parameters:

Mechanical technical parameters:

|

|

Content |

Parameter

|

|

1 |

Max. operating speed |

100m/min

|

|

2 |

Deviation-correcting device |

Multi-stage roller side positioning,accuracy±0.25mm |

|

3 |

Material thickness |

0.11mm~5mm(Use correction);Max. thickness 100mm(no need of correction) |

|

4 |

Max. feeding size |

Width 480mm*length 500mm |

|

5 |

Min. feeding size |

Width 60mm*length 90mm |

|

6 |

Feeding method |

Non-stop feeding |

|

7 |

Receiving method |

Fish scale stack receiving |

|

8 |

Dimension |

4400mm* 2250mm*1750mm

|

|

9 |

Main section length |

Feeding correction section:1300mm, printing section: 1750mm, Receiving section:1350mm |

|

10 |

Weight |

2.2T

|

|

11 |

Total Power |

8kW |

|

12 |

Power Supply |

380V±5%, 50Hz±1Hz |